GRC Silt Trap Inlets

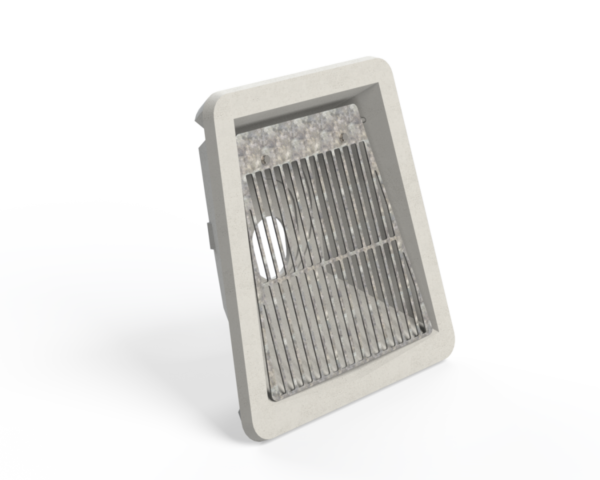

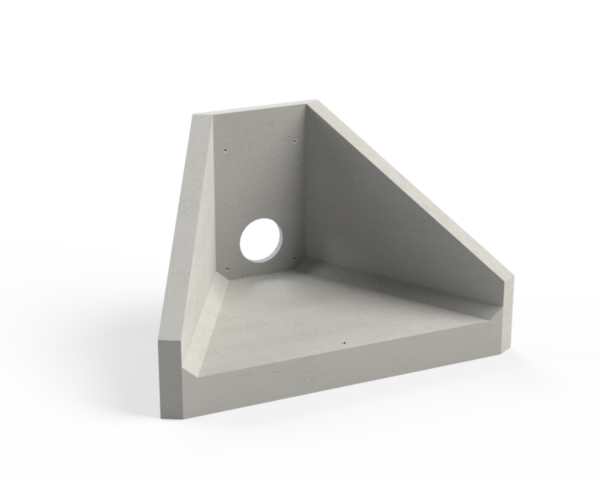

square GRC

For pipes up to 360mm O.D.

Approximate weight: 130kg.

A lightweight, easily handled moulded unit in two pieces with simple hinged grating, suitable for most situations where a piped ditch inlet needs protection. Pipe opening is formed where required by carefully knocking through with hammer and punch and opening out to required diameter. Make good with cement mortar or mastic. Particularly suitable for use with plastic drain pipes.

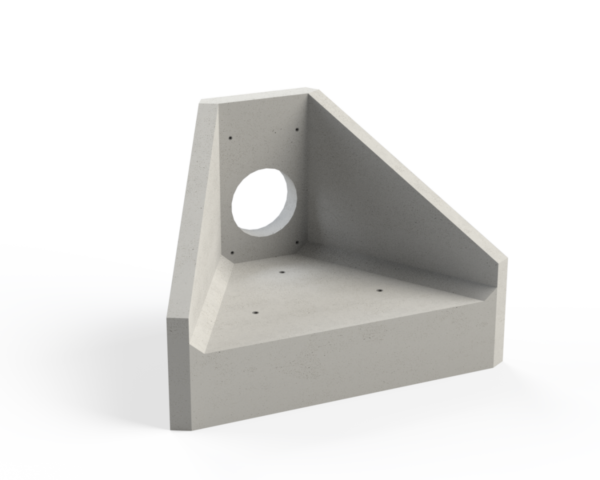

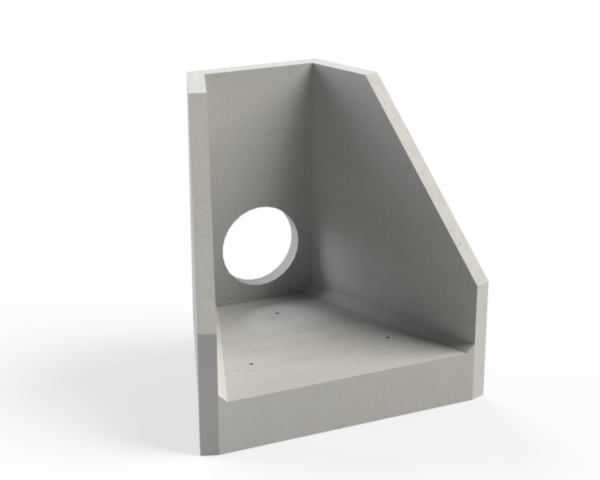

Curved back GRC

For pipes up to 360mm O.D.

Approximate weight: 130kg.

This is a one-piece moulded unit with curved back-wall which can accept pipes at any angle to the ditch line. Ideal unit for the agricultural situation with hinged sloped grating, generous silt capacity and provided with lid to prevent entry of rubbish from above. The pipe opening is formed where required by marking the position of the pipe and then carefully knocking through with hammer and punch and opening out the hole to required diameter. Make good with cement mortar or mastic.

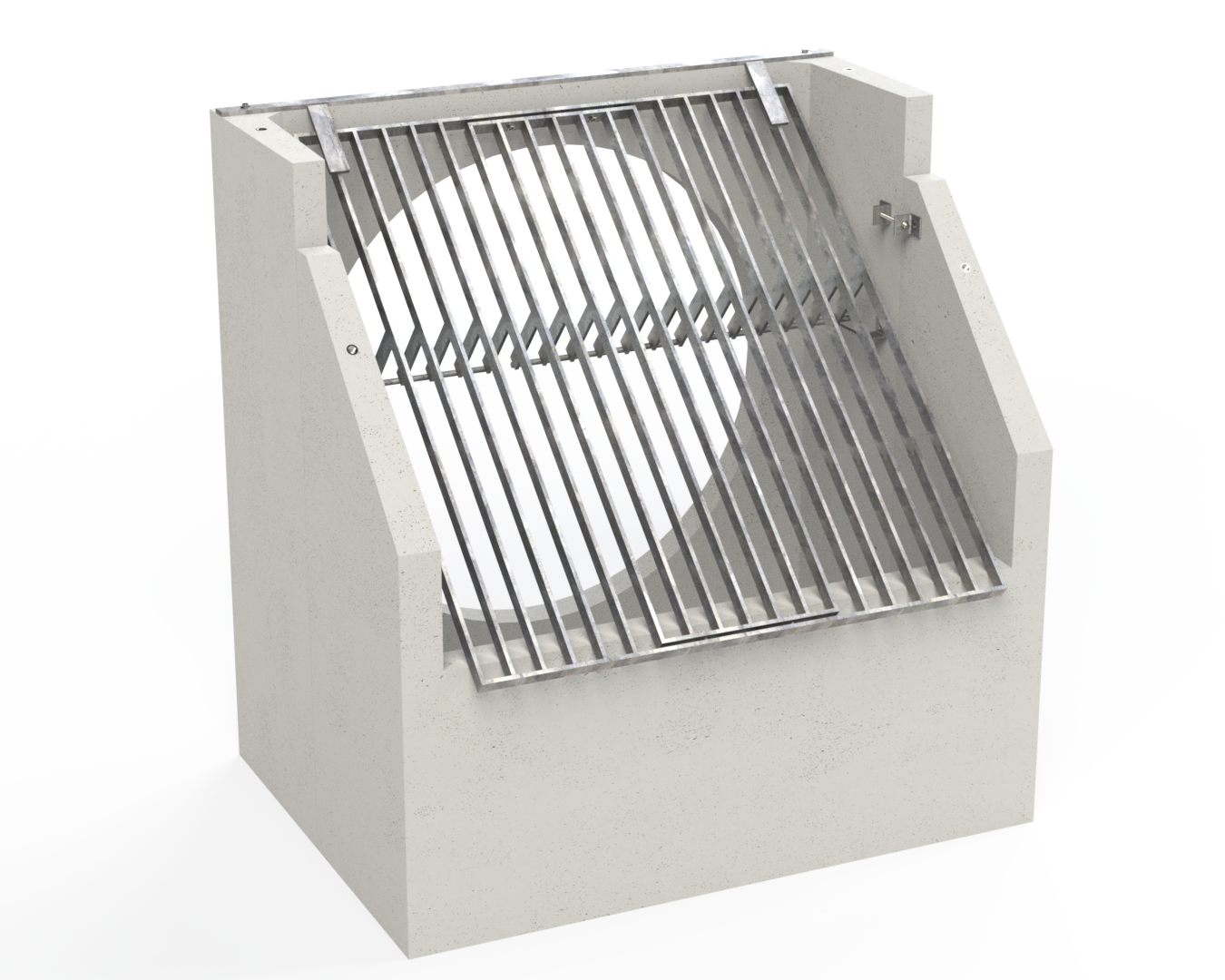

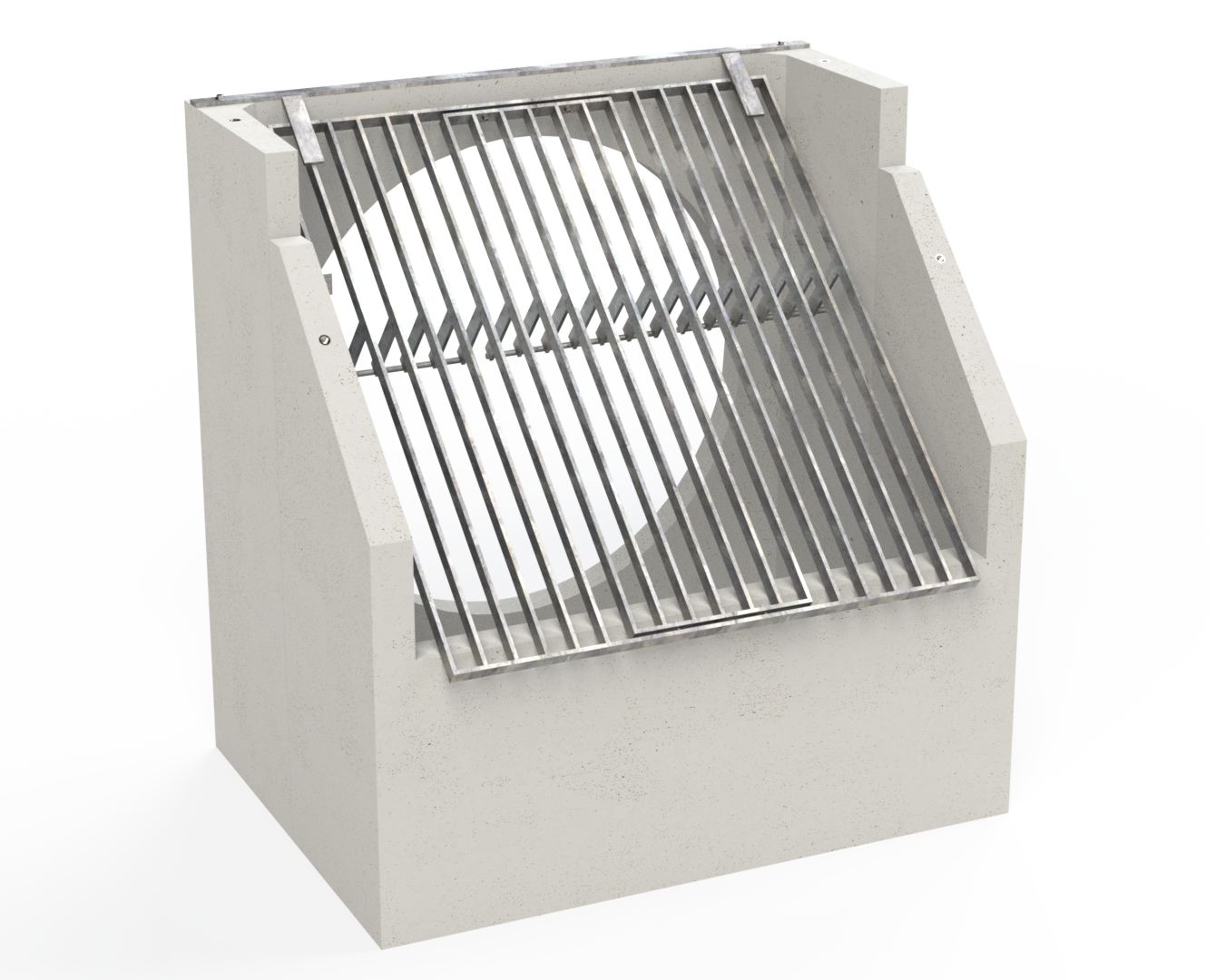

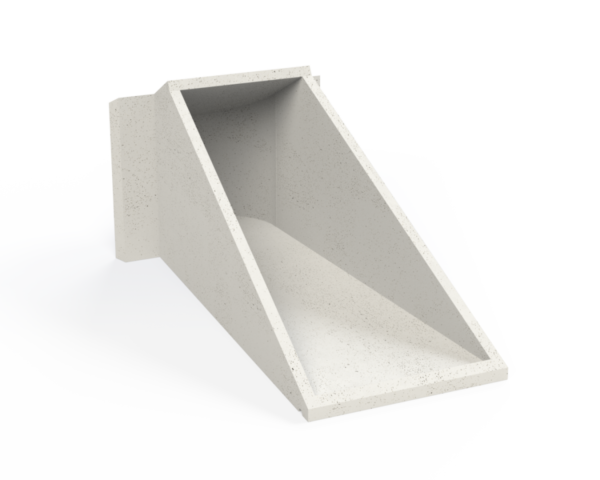

Double entry Silt Trap inlet

For pipes up to 360mm O.D.

Approximate weight: 565kg.

On some sites there is a requirement for the silt trap structure to be in the actual ditch line where it can receive water from both sides. special galvanized steel gratings are located in the aperture formed by the addition of a 300mm deep I.C. knock-out extension section to the basic sectional chamber.

Please specify the number of gratings required when ordering this unit, as it is priced with only one.

- Made to Order – Leadtime 2-4 week