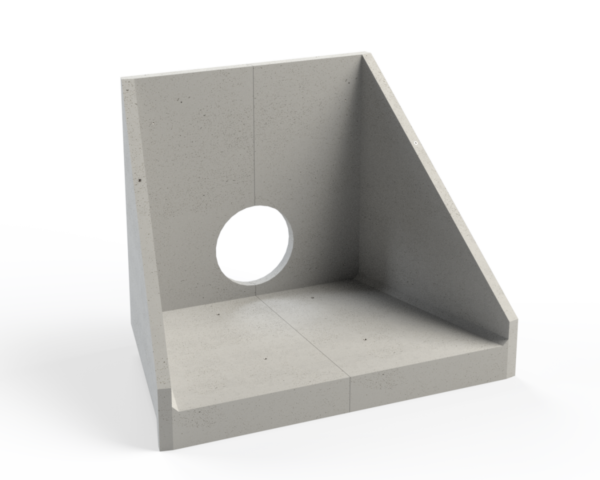

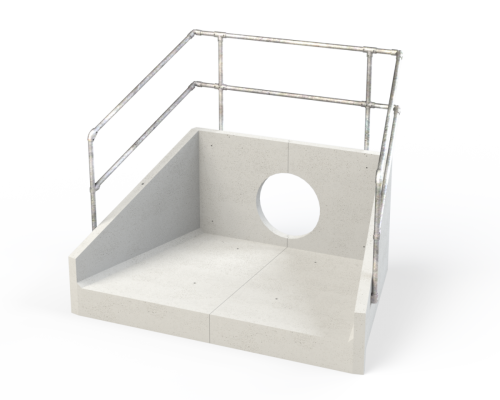

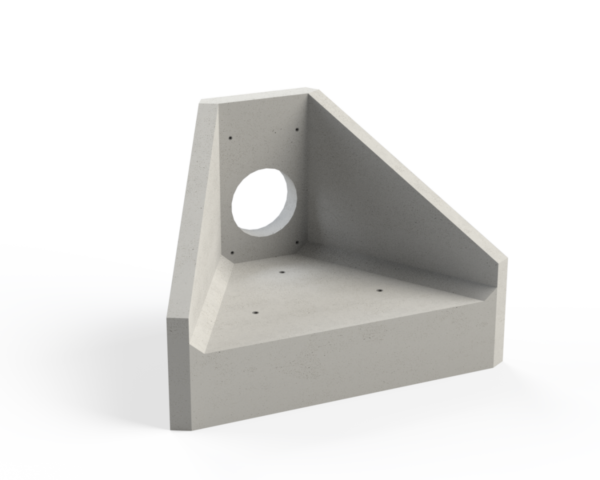

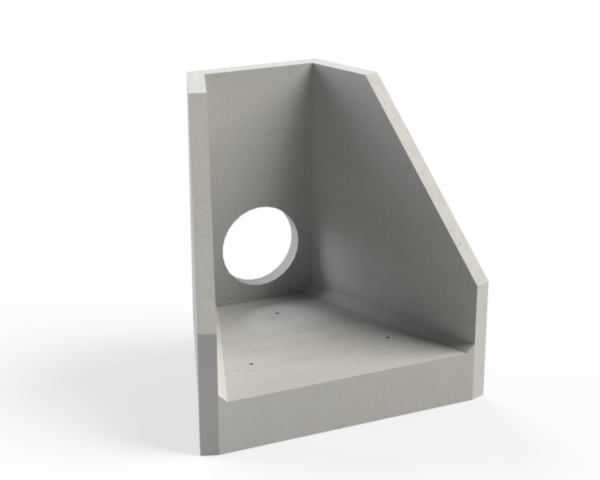

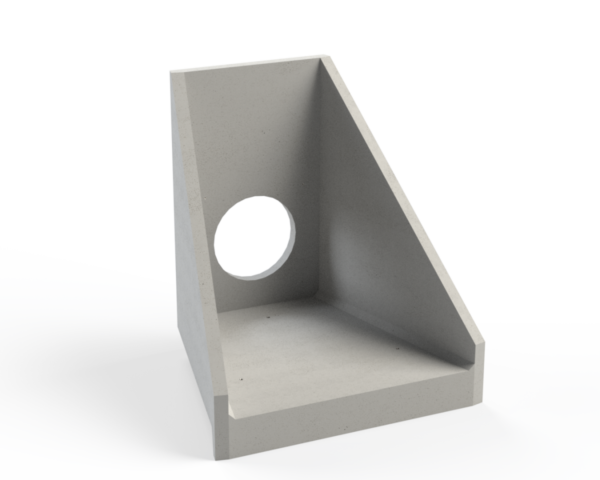

2000 Series Headwall

This is a sectional structure with rebated sides, assembled on site around the drainage pipe and locked together by the means of stainless steel cast-in sockets and brackets provided. This headwall is designed for pipes with an outside diameter over 1000mm up to a maximum of 2000mm OD. Three standard versions are available with wing walls at differing batter angles. M20 lifting points are cast in for use with RD20 lifting loops.

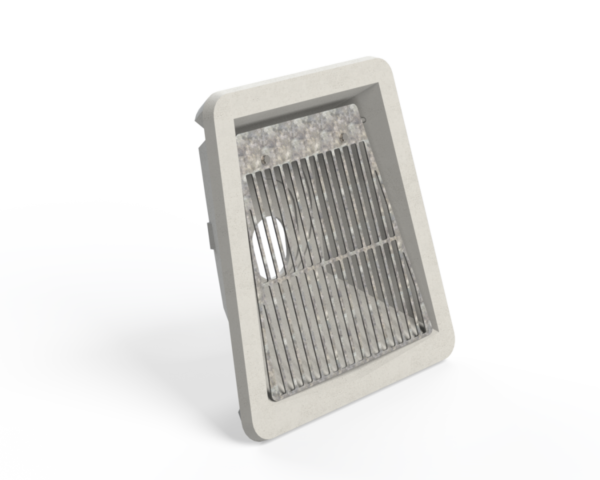

Various types of heavy duty galvanised steel gratings or stainless steel gratings can be supplied which are bolted to the stainless steel sockets cast in. Brackets are available for use with the ground anchor system. Provision can be made for fixing tidal flaps, penstocks and other devices. All our precast headalls are made to order to suit the diameter and position of the pipes being used.

- Made to order – Leadtime 2-4 weeks.

2000 Series Dimensions

| Max. Pipe Opening | Height Options Available (mm) A | B (mm) | Approx. weight (kg) | Maximum pipe size (mm) |

|---|---|---|---|---|

| 900 | 1250 | 300 | 2600 | 750 ID twin wall 750 ID concrete |

| 1150 | 1650 | 700 | 3200 | 1050 ID twin wall 1050 ID concrete |

| 1800 | 2130 | 200 | 3600 | 1500 ID twin wall 1500 ID concrete |