memorial bases

Memorial Bases: Durable Solutions for Structural Integrity.

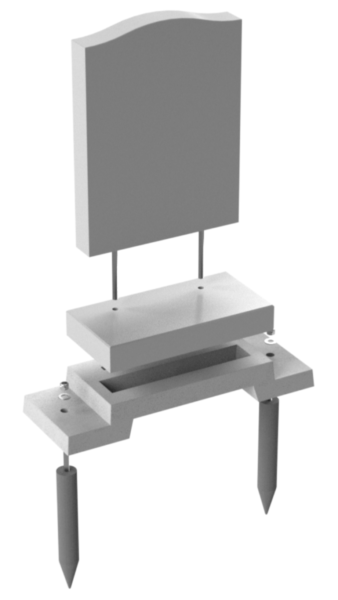

Ensuring the proper foundation for headstones is critical for the stability and longevity of memorial bases, as they are essential for keeping the upper headstone slab upright and securely in place. Poor-quality foundations can lead to sinking or tilting of the memorial, compromising its integrity. At JKH, we pride ourselves on being a leading supplier of high-quality, steel-reinforced concrete memorial bases, offering a comprehensive range of solutions from small memorial bases to specialised war grave saddles, designed to effectively support any headstone.

customisation and solutions

Memorial Base Solutions.

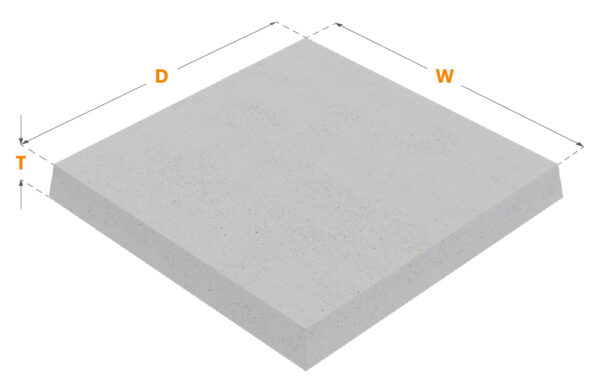

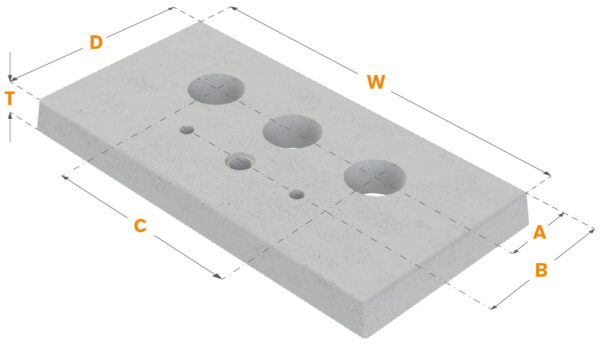

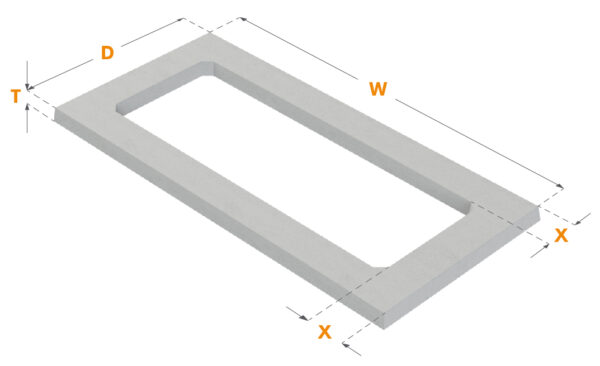

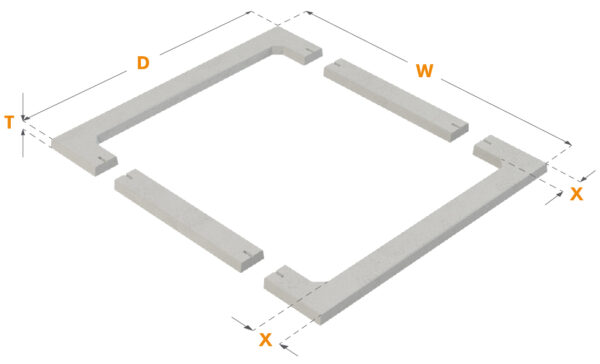

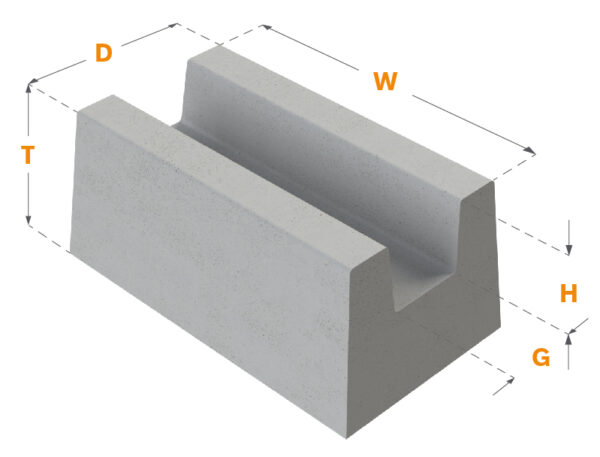

We offer a variety of foundation slabs manufactured to BS 8415:2018 standards, available in sizes with 1-inch thick stock bases, and made-to-order 2-inch and 3-inch bases. Each slab can include options for one or three vase holes. Our saddles and war grave saddles are designed for memorials and Commonwealth war graves, available in standard sizes and a special 35″ x 15″ x 6″ size, with standard saddles sold individually and war grave saddles in pallets of 12 for bulk delivery. Additionally, our small memorial bases are made from steel-reinforced concrete and offered in sizes ranging from 34″ x 36″ x 3″ to 36″ x 36″ x 3″, customisable with vase or dowel holes upon request.

jkh solutions

Whatever YOUR needs, we can provide the most effective solution.

If you have any questions or need assistance selecting the perfect memorial base for your project, please don’t hesitate to reach out to us. Our knowledgeable team is here to help you find the right solutions to meet your needs and ensure a lasting tribute.

providing the solutions for a whole range of industries

DESIGNED. PRODUCED. DELIVERED.

WE DESIGN.

Our in-house design team, skilled in SolidWorks and AutoCAD, brings extensive experience and innovation to every project. From concept to production drawings, we create tailored solutions that simplify complex requirements.

We focus on designing products that minimise onsite challenges, ensuring smoother installations and saving time and resources. We’re dedicated to delivering precise, practical designs that work seamlessly for you.

WE produce.

Our 250,000 sq ft manufacturing facility in Suffolk is equipped with advanced machinery for high-quality steel fabrication and concrete casting. With over 150,000 headwalls produced to date, we have the expertise to bring your vision to life. We manage the entire process—from initial consultation and steel fabrication to concrete casting and delivery—ensuring flexibility and adaptability.

WE DEliver.

We pride ourselves on our efficient nationwide delivery service, with stock items dispatched within 2-3 days. Our FORS silver accredited fleet of vehicles, equipped with cranes on request, ensures reliable transportation and offloading support. At JKH, we are committed to delivering high-quality products quickly and efficiently, helping you meet your project timelines without compromise.

Reduce your CO2 EMISSIONS WITH ECO 1

-

46-70%

cement reduction

-

12-49%

CO2 Reduction

-

100%

JKH standard PRODUCTS USE ECO 1

get in touch

Let’s Discuss Your

Concrete Needs.

Contact us today to discuss how our expert team can provide the perfect drainage solution for your project.

Call us on 01638 713795

email us onsales@jkhltd.co.uk