chambers

Concrete chaMbers: Durable Solutions for Structural Integrity.

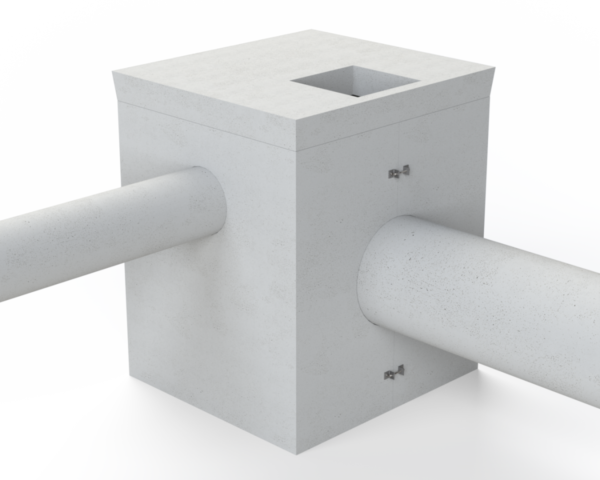

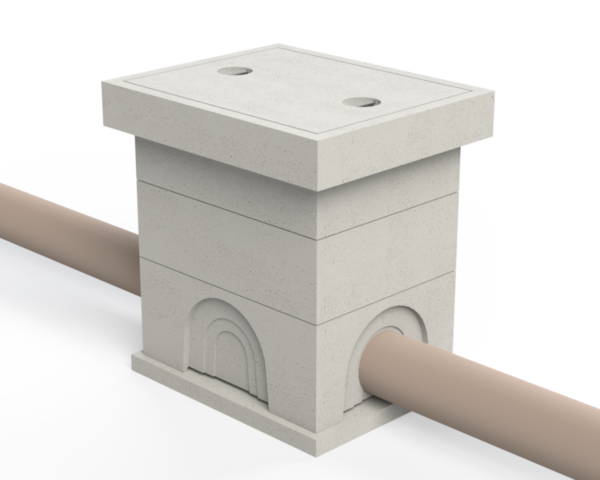

Normally installed at all changes of direction in a main drain, chambers are essential for providing rodding points in a long run of drain.

Chambers are also used for the connection of lateral drains at various depths and for use as tumbling bays where it is required to slow the drainage water down on steep sloped sites.

Tailored Concrete SOLUTIONS: Custom Designs for Specific Requirements.

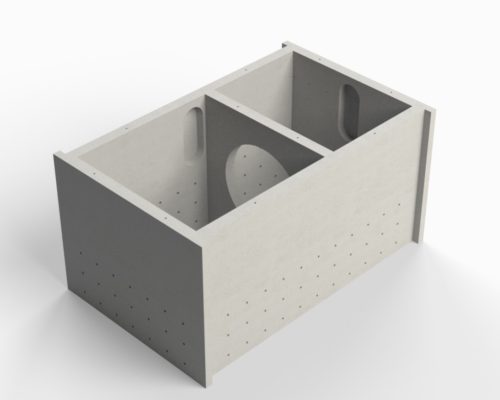

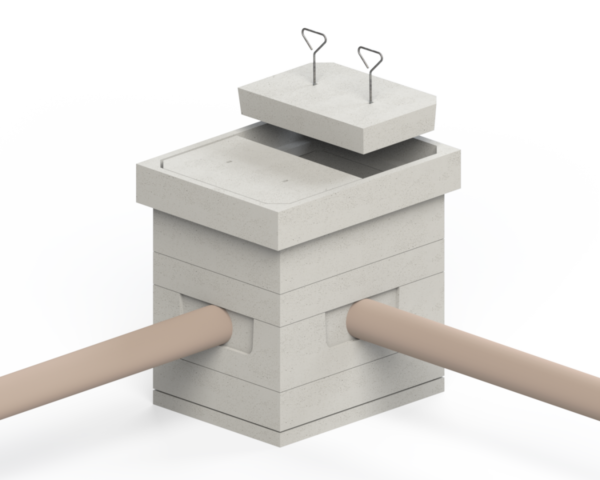

As well as our extensive range of stocked and made to order standardised precast chambers, we can also custom design any product to your specific requirements.

Our experienced design team specialises in creating bespoke solutions tailored to your specific needs, ensuring every aspect of your project is addressed. We also offer Glass Reinforced Cement (GRC) as a lightweight and durable alternative, providing a cost-effective option that enhances the efficiency and longevity of your drainage system.

products

standardised concrete chambers.

JKH manufacture a range of precast chambers that cater for all pipe sizes up to 1400mm outside diameter.

CUSTOMER TESTIMONIAL

bespoke Soakaway chambers:

We found the product very easy to use on site. The precast units are lightweight and could be lifted into position by our 360 excavator without the need for cranes. The units where bolted together in a matter of minutes by our groundworkers and came with ‘knock out’ sections to allow the pipework to easily connect into the soakaway avoiding further time and cost to make the holes.

We would certainly recommend this product and look to use it on other projects in the future

– PB Doyle Construction Limited

Reduce your CO2 EMISSIONS WITH ECO 1

-

46-70%

cement reduction

-

12-49%

CO2 Reduction

-

100%

JKH standard PRODUCTS USE ECO 1

providing the solutions for a whole range of industries

DESIGNED. PRODUCED. DELIVERED.

WE DESIGN.

Our in-house design team, skilled in SolidWorks and AutoCAD, brings extensive experience and innovation to every project. From concept to production drawings, we create tailored solutions that simplify complex requirements.

We focus on designing products that minimise onsite challenges, ensuring smoother installations and saving time and resources. We’re dedicated to delivering precise, practical designs that work seamlessly for you.

WE produce.

Our 250,000 sq ft manufacturing facility in Suffolk is equipped with advanced machinery for high-quality steel fabrication and concrete casting. With over 150,000 headwalls produced to date, we have the expertise to bring your vision to life. We manage the entire process—from initial consultation and steel fabrication to concrete casting and delivery—ensuring flexibility and adaptability.

WE DEliver.

We pride ourselves on our efficient nationwide delivery service, with stock items dispatched within 2-3 days. Our FORS silver accredited fleet of vehicles, equipped with cranes on request, ensures reliable transportation and offloading support. At JKH, we are committed to delivering high-quality products quickly and efficiently, helping you meet your project timelines without compromise.

get in touch

Let’s Discuss Your

Concrete Needs.

Contact us today to discuss how our expert team can provide the perfect drainage solution for your project.

Call us on 01638 713795

email us onsales@jkhltd.co.uk