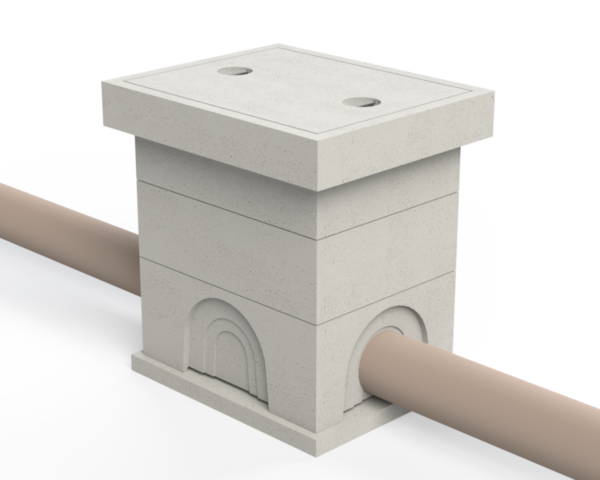

Big J Inspection Chamber

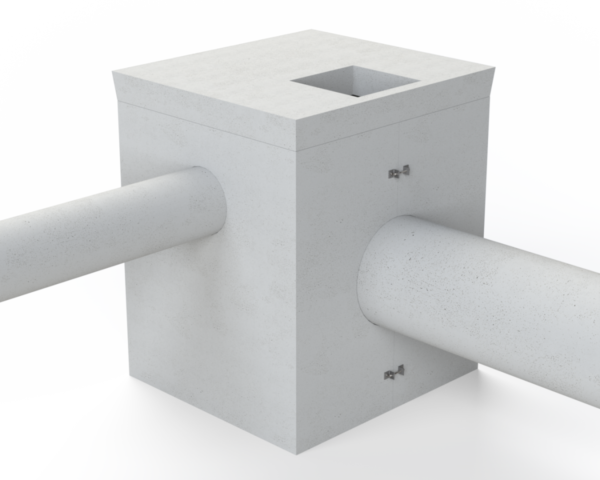

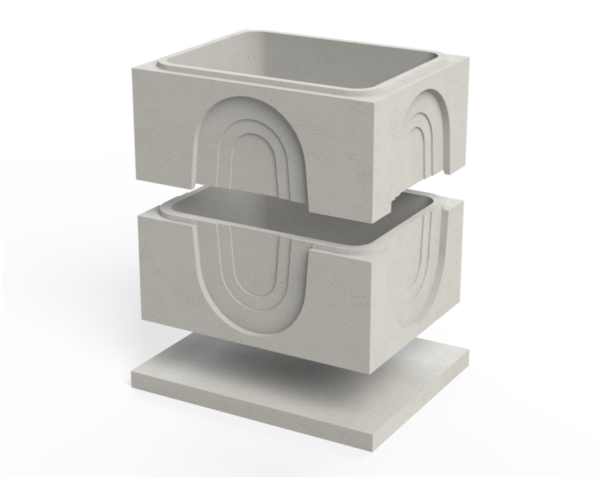

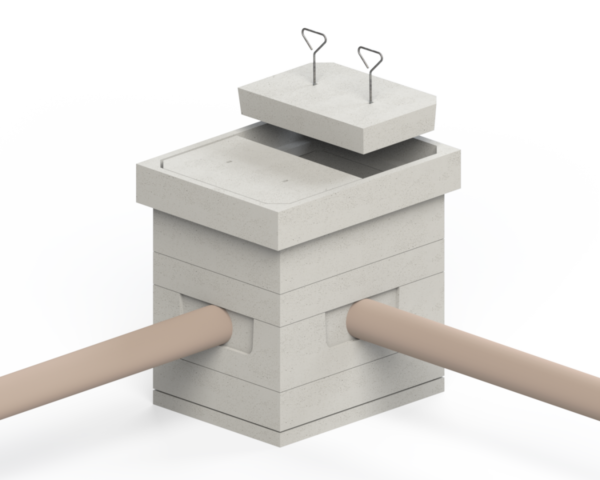

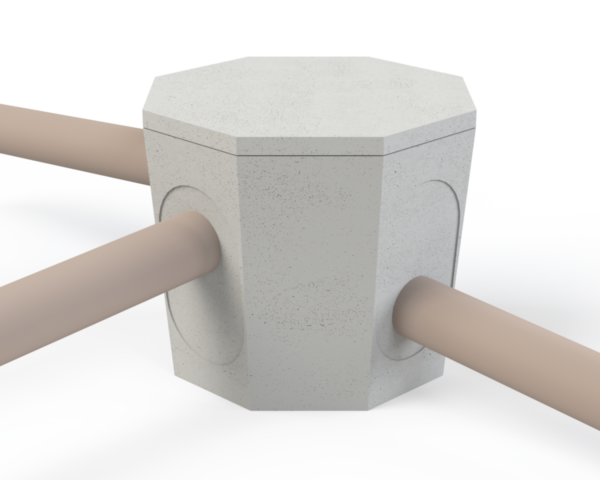

A new concept in chamber design. A two-piece unit where the base is integral with the sides. The required pipe openings are cast-in at any desired position, no brickwork or shuttering is required, no awkward holes to be cut. Big ‘J’ chambers are supplied complete with galvanized step irons and all necessary fixings and come complete with heavy duty cover slabs and manhole access. All units have special lift points cast.

Machine-made reinforced concrete sections to BS.5911 part 2 are fitted on the lid of the Big ‘J’ chamber to extend the opening to ground level. Standard 600mm x 600mm galvanized 17 tonne GVW pressed steel manhole covers cast into a 100mm thick concrete surround are available to fit these units.

- Made to order – Leadtime 2-4 weeks.

| BIG ‘J’ SIZE | (D) 1220 x (W) 1070 | (D) 1630 x (W) 1070 | APPLICATIONS |

| Height (H) of basic chamber | 810mm 1120mm 1420mm 1735mm 2030mm 2340mm |

810mm 1120mm 1420mm 1735mm 2030mm 2340mm |

Manhole

Piped Ditch Inlet Tumbling Bay Flow Meter Box Pumping Sump Siphon Pit Effluent Storage |

| Maximum O.D. of pipe recommended | 830mm | ||