Standard Grating Designs

Gratings are mainly used to stop debris, people and animals from entering pipes. Sloped and cranked gratings are used in areas with high levels of debris, as they are more resistant to blockages, or to protect flap valves.

JKH manufacture a range of gratings to cover all sizes of pipes, including to SFA Sewers For Adoption standard. Manufactured in mild steel, hot dip galvanized and provided with suitable brackets for mounting directly to the headwall structure. Special gratings made to customers specifications can be manufactured in mild steel or stainless steel on request.

Close coupled gratings: Used as a cost effective debris and safety screen, stopping unauthorised access into pipes.

Sloped gratings: Used as a debris screen on the upstream end of a pipe where there is a higher change of blockage. The sloped grating has a higher surface area and allows debris to be pushed up its face by the flow, reducing the chance of blockage. The sloped design can easily be raked.

Cranked gratings: Used to protect flap valves from damage and vandalism, or to allow raked up debris to drain before removal.

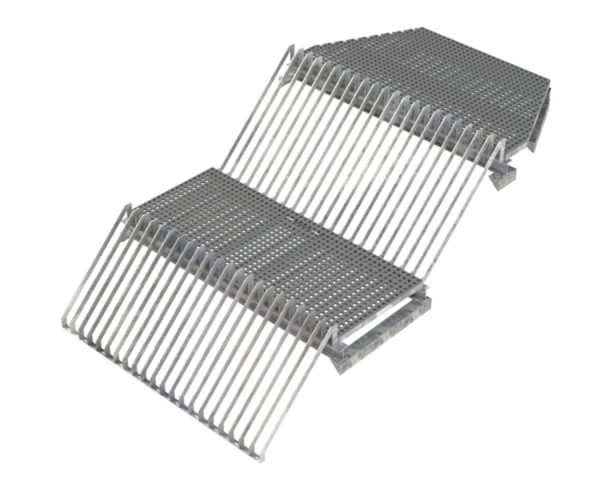

SFA gratings: Used on headwalls that will be adopted by the local water authority. These heavy duty hinged gratings are made to the Sewers For Adoption 7th edition guide lines.

Hinged close coupled gratings: Used as a cost effective debris and safety screen where regular access is required. These have padlock points to allow quick access.