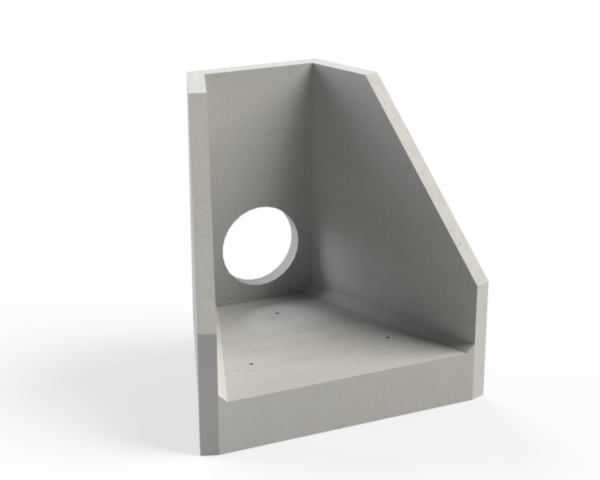

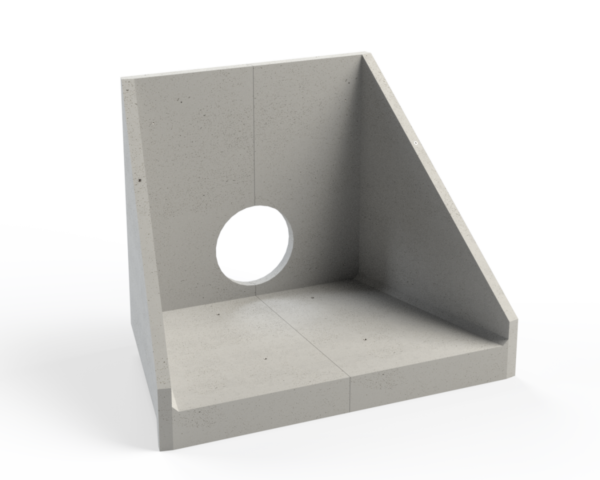

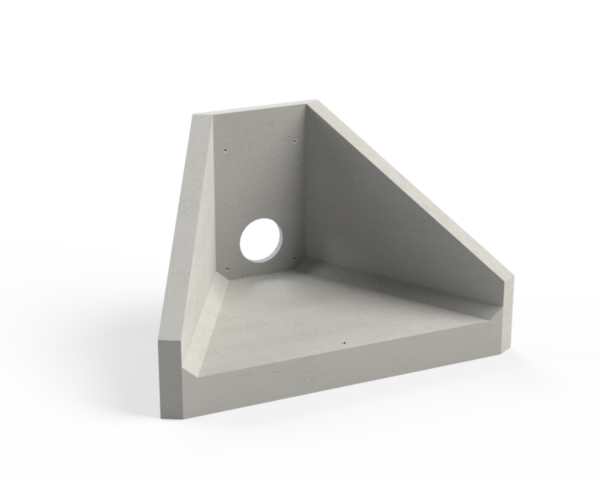

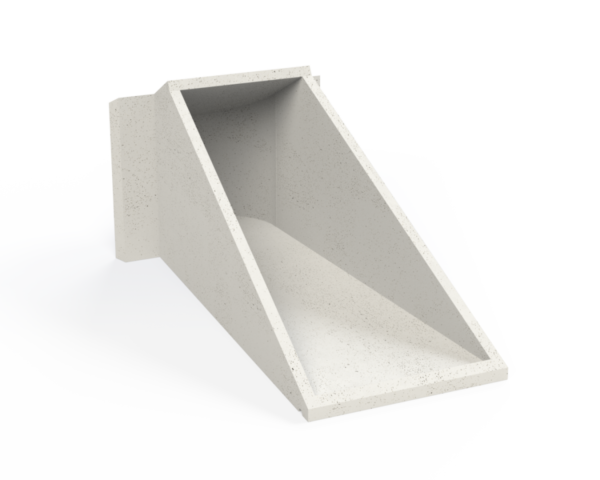

Water Control Headwall

Approximate weight: 700kg. – 1400kg.

suitable for pipes up to 1400 O.D.

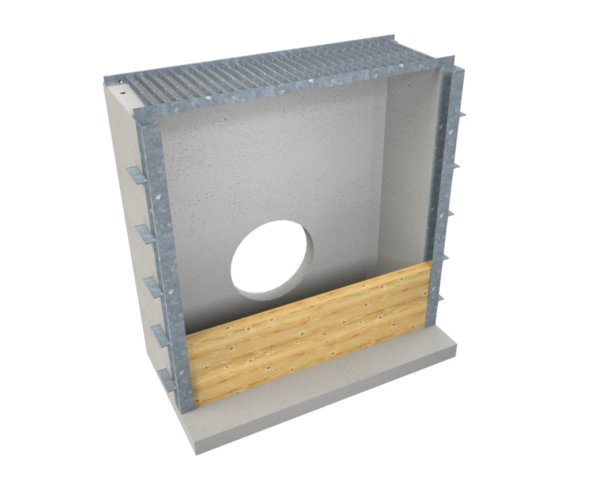

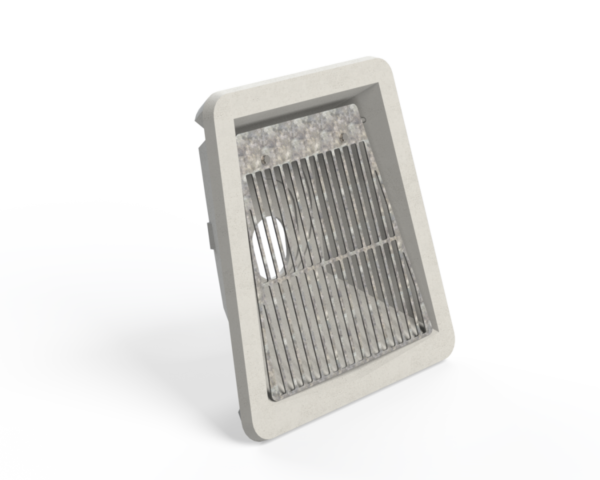

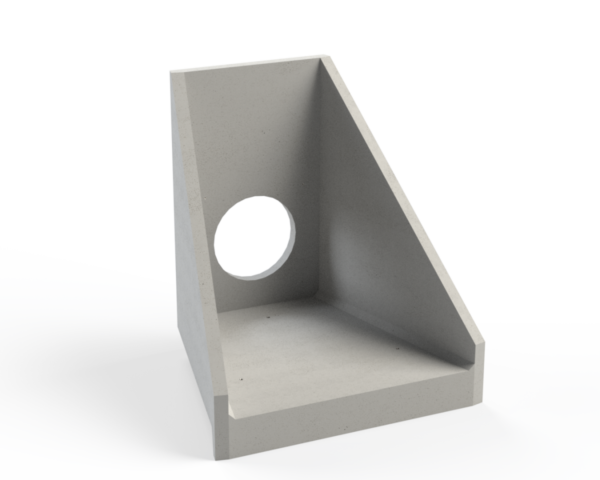

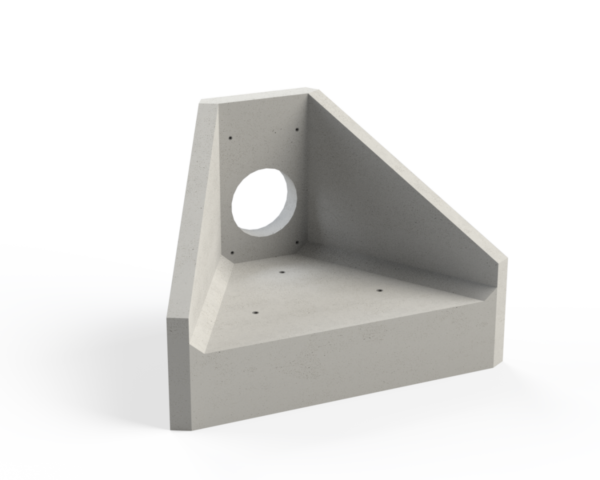

A pre-cast reinforced concrete unit available in three standard widths for assembling at the inlet of a piped culvert. It incorporates the facility to install removable wooden boards in steel slides for controlling the water levels in farm dykes. Additional slides may be provided at the sides of the unit to accommodate 75mm thick concrete wall panels (maximum size of panel 2250mm x 3000mm long). These are let into the banks at each side to give complete protection. All the units have special cast-in lift points. Provision is made for extension sections to be fitted where a higher structure is required.

Please note these are available with wooden or aluminium stop logs.

- Made to Order – Leadtime 2-4 weeks

| Width of Headwall (mm) A | Height option available B (mm) | ||||

|---|---|---|---|---|---|

| 1070 | 1120 | 1420 | 1730 | 2035 | 2340 |

| 1375 | 1120 | 1420 | 1730 | 2035 | 2340 |

| 1680 | 1120 | 1420 | 1730 | 2035 | 2340 |