Metal trash screens are an essential element of most water processing sites, both large and small. Without them, the risk of flooding is increased significantly. Their function is to prevent blockages and keep water flowing as it should. But, there’s a lot more to it than that. Different situations require different solutions, and the design and manufacture of metal trash screens are a specialised field.

Here at JKH Ltd we work closely with our customers to create the perfect solution, whatever the problem. Our skilled designers will find the most cost-effective option, which will be manufactured to the highest standards. Read on to learn more about trash screens and the range of products available at JKH Ltd.

How do trash screens work?

The biggest hazard for any kind of watercourse is the risk of getting blocked. A blockage can cause flooding, and this can be damaging and costly. One of the most efficient ways of preventing blockages is through the use of steel grating. This allows water to continue to flow while trapping unwanted household waste or foliage.

Trash screens are frequently used in narrow waterways such as culverts, pipework and drainage systems. They are also found at water treatment facilities, and wherever flowing water needs to be kept free of debris.

Metal trash screens are available in a variety of designs and sizes, depending on requirements.

Efficient design

Where a culvert or similar feature creates a bottleneck in a watercourse, blockages are likely to occur. In situations like this, a trash screen can help to reduce the risk. But, if not properly cleaned and maintained, the grating itself could increase the risk of flooding. Trash screens are therefore designed with access and maintenance in mind, allowing the screen to do its job.

Bespoke solutions

There are standard metal trash screens available to suit many situations, but sometimes a standard product isn’t the right fit. At JKH Ltd we have the knowledge and experience to provide the perfect bespoke solution.

The proposed location of the screen is surveyed to assess what type and size of debris might accumulate there. This could range from large household items to organic waste such as leaves. Using this information, the appropriate bar spacing can be incorporated into the design. The angle of the grating may also affect how well it works, and that, too, will be taken into account. The screen will be manufactured off site to the most rigorous standards, using high quality materials.

Products available from JKH Ltd

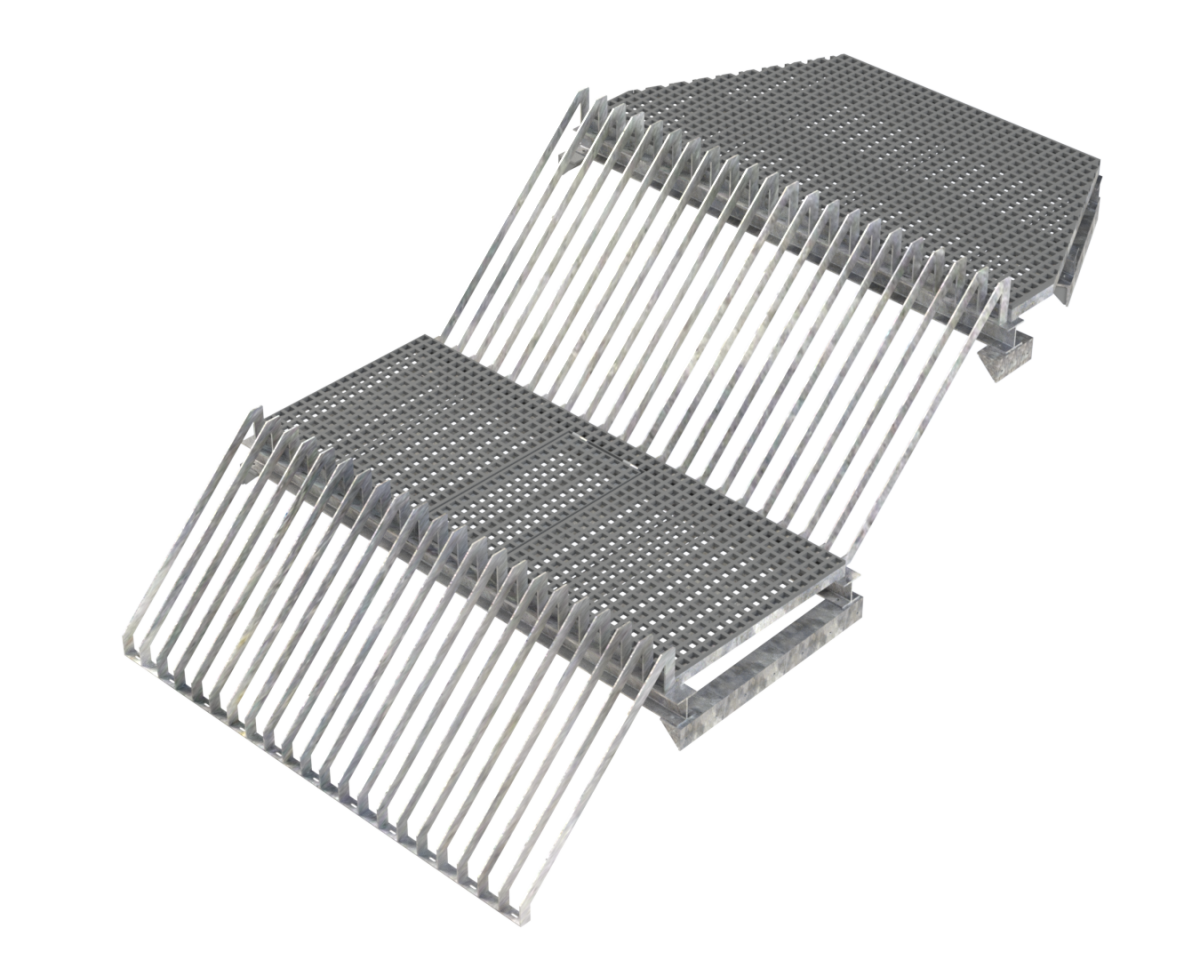

Our skilled designers are able to create metal trash screens to suit customers’ specific needs. A recent project was a double crank grating, with GRP safety mesh on the flat sections. Delivered in parts and rapidly assembled on site, it included a central access hatch.

Additional products include a selection of standard and bespoke gratings, as well as catwalks, handrails and vermin gates. Visit our website to see the range of steel security and trash screens available at JKH Ltd, or contact us today for more information.